PCB assembly services

Quality assured PCB assembler, supplier and designer

Interconics have been assembling printed circuit boards for over 20 years, giving us a level of experience and expertise in the pcb assembly and production process that is hard to match.

To ensure we continue to provide the same high standards of PCB assembly that we have become known for, we are constantly looking into the future to ensure we are ahead of the curve and up-to-date with the latest trends and technology.

At Interconics, we invest heavily in both the people and in new technologies so that we are always on step ahead of our competitors. It is this constant drive towards improvement that allows us to position ourselves as one of the top PCB assemblers in the UK, with leading technical capabilities that put us at the forefront of PCB assembly and manufacturing in the country.

Give us a call on +44 (0)1225 700108 to enquire further about our first-class PCB assembly service.

Why use Interconics for your PCB assembly needs?

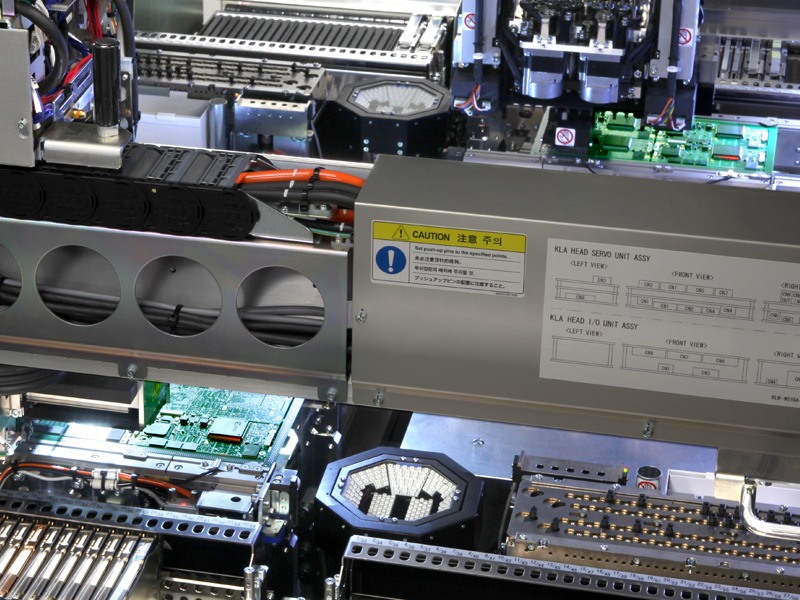

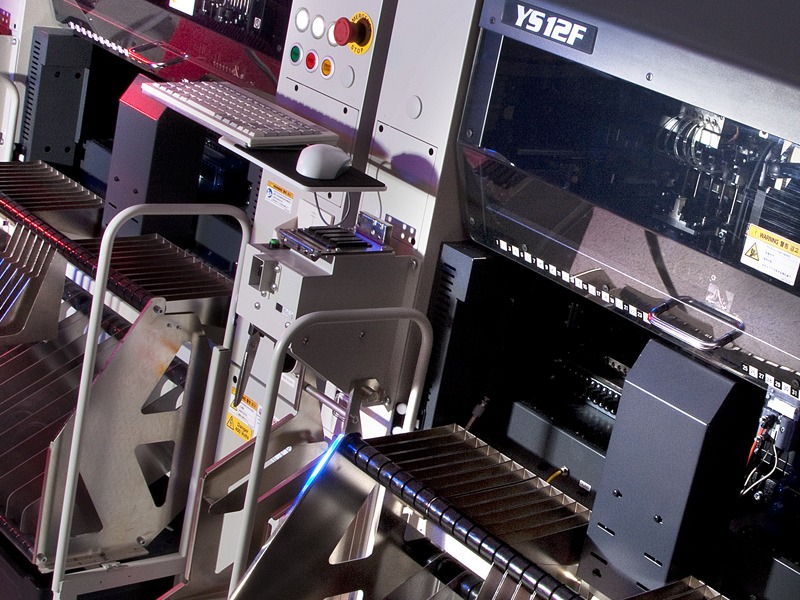

Here at Interconics, we have recently upgraded our entire production suite to top of the range Yamaha equipment capable of placing tiny 03015 metric (1/4 of the size of imperial 0201) components with perfect accuracy.

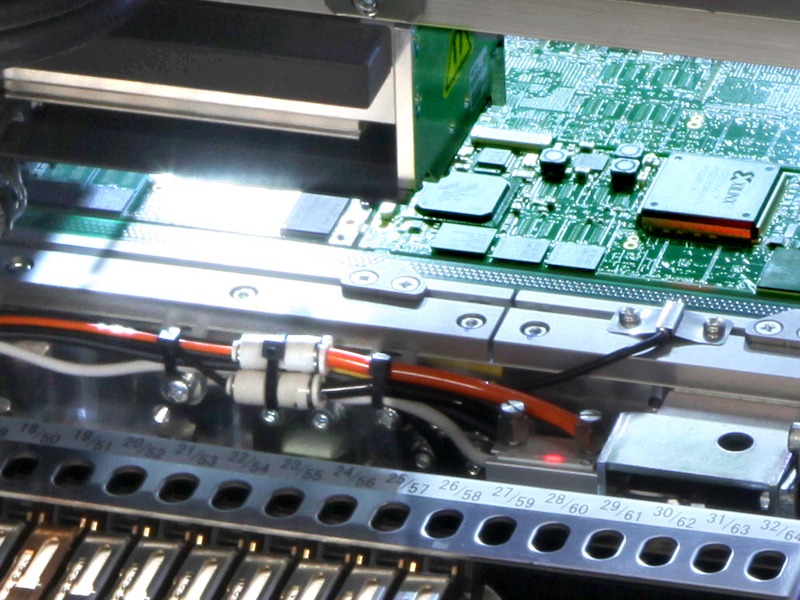

This means we can ensure exceptional build quality with great lead times on even the most advanced PCB designs. In addition to our exceptional assembly services, we offer a multitude of value-added services to improve your products, including; Conformal coating to increase water resistance and improve in-field product life cycles and BGA/CSP Underfill to improve mechanical resistance to shock and vibration and reduced thermal expansion issues due to increased thermal transfer between component and printed circuit boards.

We offer many more value-added services to improve your product, including robust PCB inspection and component sourcing. Please get in touch with us to find out more.

Benefits of our PCB manufacturing & assembly service

Using an experienced and trustworthy partner for your PCB manufacturing and assembly needs can benefit your end product by assuring a high-quality build, whilst also saving your business time, costs.

Some the prime benefits of using Interconics PCB assembly service are:

- High-quality production: We use advanced equipment and technology to ensure that your printed circuit board assemblies are produced to a high standard, with precise production controls with machine learning and consistent quality.

- Faster turnaround time: Our engineers offer a level of expertise and equipment that helps us assemble printed circuit boards quickly, reducing the time it takes to bring your product to market.

- Cost savings: Our PCB assembly services offer excellent opportunities to save costs, from small to medium volume right up to serial production runs.

- Design assistance: We also offer PCB design assistance and guidance, helping our clients optimise their designs for manufacturing and identify potential issues that could impact performance or manufacturability later down the line.

- Expertise: Interconics boasts specialised expertise in the design and production of circuit boards, meaning we are fully equipped to handle complex projects, and can offer our expert advice and recommendations to see your project through to completion.

Our fully automated SMT production lines contain :

ESD controlled PCB cleaners capable of removing any foreign particles and any static charge from PCBS before they enter production.

Automated screen printers capable of printing the smallest components on the market with full inspection and perfect repeatability. With versatile stencil technology including; nano polishing, stepped stencils and nano coatings we can ensure that you get perfect solder joints every time.

Pick and place machines capable of placing from 0.3×0.15mm components and 0.25mm pitch BGA devices up to 55x100mm components at up to 90,000 components per hour per machine. With placement accuracy of +/-0.025 @ 3σ we can guarantee a reliable, repeatable placement of any component.

Perfectly controlled multi zone reflow ovens with ideal conditions for repeatable solder joint reliability. Our experienced production technicians have over 20 years of experience in reflow profiling, across all levels of PCB technology.

Automated loading and unloading equipment to minimize manual handling of PCBs. With the need for automation and traceability growing rapidly as we embrace and implement our Industry 4.0 plans, having fully automated PCB handling in our production facility is more crucial than ever.

Get in touch today to enquire further about our services. Conveniently complete our online enquiry form or give us a call directly on +44 (0)1225 700108.