Solder free technology

Quality assured PCB assembly, supply and design

Solder-free technology is a robust and environmentally friendly approach to PCB production, eliminating the risks associated with heat damage, lead contamination, and inconsistencies in solder quality, whilst optimising assembly cost-effectiveness.

This game-changing technology is crucial in addressing the complexities of modern electronic design and ensuring enhanced product longevity.

Read below to find out more about our solder free PCB production at Interconics, or give our sales team a call on +44 (0)1225 700108 to enquire further about your project and needs.

Types of solder-free connections and their applications

In the world of solder-free connections, two innovative solutions particularly stand out:

- Press Fit Connectors

- Semi-Flex PCBs.

These technologies are transforming the way we conceive and construct PCBs, providing enhanced reliability and streamlined production processes.

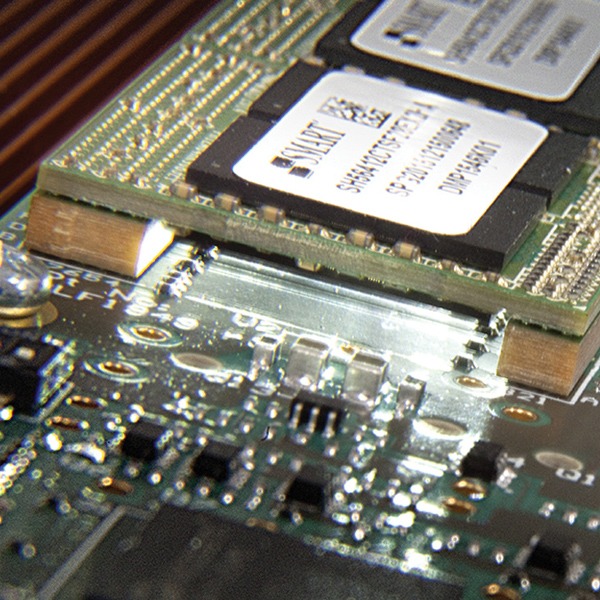

Press Fit Connectors

Press fit connectors are an increasingly popular choice in fast PCB production.

Press fit connectors are components that are pressed into pre-drilled holes on the PCB board. This technique entirely bypasses the need for soldering, thus eliminating the potential for heat damage and the environmental concerns of lead-based solder.

The press fit method offers significant advantages over traditional through-hole connection options.

Semi flex PCBs

Semi-flex PCBs are a recent development in the PCB industry, offering an excellent solution for creating inter PCB links and edge connections with no need for soldered connectors at all.

Essentially, these are rigid PCBs with flexible sections, designed to flex only once during the final installation.

This single flexing capability significantly reduces assembly time and cost while also enhancing the reliability of the end product.

By eliminating the need for soldered connections, semi-flex PCBs provide a consistent and efficient approach to implementing PCB to PCB connections.

Get in touch today to enquire further about our services. Conveniently complete our online enquiry form or give us a call directly on +44 (0)1225 700108.