Here at Interconics we are always looking to increase reliability and repeatability on all aspects of PCB assembly, one of the most crucial stages in this process is the correct and accurate printing of solder paste onto the PCB.

With constant advancements into miniaturization and optimization of PCB land space usage, electronics design engineers and PCB layout engineers are striving to decrease the amount of space used up by components.

This means that the contact pads of these devices must be smaller than ever before. Being able to pick and place small components is only part of the puzzle; a major cause of poor PCBA reliability is incorrect solder paste application.

Correct solder stencil design is crucial in getting the correct amount of solder on the contact pads of your product. Here at Interconics we check all solder stencil files before sending them to manufacture. We check that the solder mask, copper and solder paste layers are all suitable for manufacture. As well as this we will advise on surface finish if we think that the surface finish might not be suitable for the technology level of the PCB. Some surface finishes such as hot air level (HAL) are not suitable for components with pitches below 1mm we suggest using a more level finish.

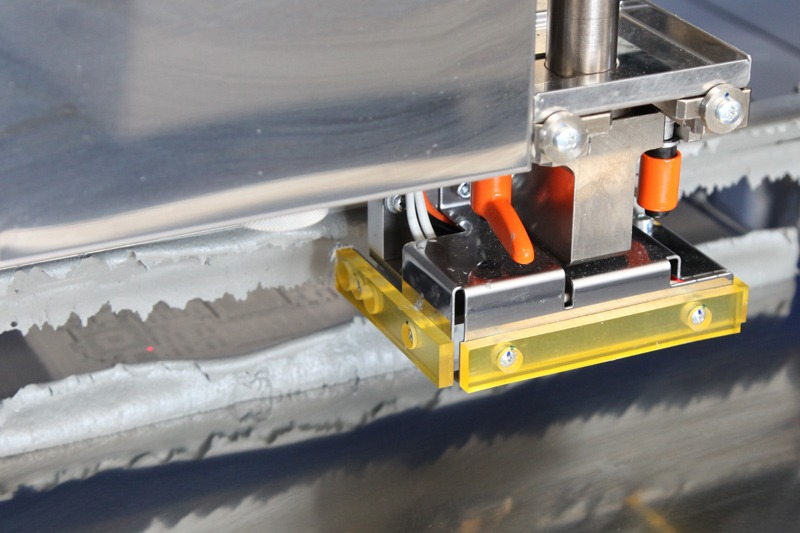

Yamaha solder paste printing equipment

We have recently implemented Yamaha solder paste printing equipment onto all of our production lines, with class leading printing accuracy and repeatability (+/- 0.005mm @ 3σ) this equipment allows us to print even the smallest of apertures. With full optical inspection and volume measurement built in, the machine is capable of using this inspection data to self optimize and increase accuracy.

The equipment is only ever as good as the programmer; our assembly technicians are highly experienced in solder paste printing setup parameters. Depending on stencil thickness, aperture sizing, solder paste used and technology level of the stencil we can use our knowledge to set the squeegee angle, squeegee pressure and print speed. This will greatly affect the way the solder “releases” from the stencil onto the PCB.

The equipment is only ever as good as the programmer; our assembly technicians are highly experienced in solder paste printing setup parameters. Depending on stencil thickness, aperture sizing, solder paste used and technology level of the stencil we can use our knowledge to set the squeegee angle, squeegee pressure and print speed. This will greatly affect the way the solder “releases” from the stencil onto the PCB.

The solder paste stencil is just as important as the equipment that it is used by, if the stencil is the incorrect thickness or has incorrect aperture sizes then you will never have a reliable solder joint. Here at Interconics we are experts in solder paste stencil design and can promptly assess the solution needed to achieve a reliable, repeatable result.

With a multitude of technology levels available including stepped stencils, Nano coatings and stencil hole polishing we can promise an excellent application of solder paste on all of our assemblies.