PCB Technical Capabilities

Quality assured PCB assembly, supply and design

Interconics offer class leading electronics manufacturing services.

Here at Interconics we provide a tailor made CEM service with all of the support and guidance you need to move from concept to volume production.

With outstanding staff, class leading equipment and exemplary service we deliver the value added flexible supply chain management you deserve.

Bare PCBs

Through our network of carefully chosen partners, we can provide high quality PCBs with excellent lead times in any quantity.

This means we can help you to compete in your price sensitive market without compromising your high standards.

Standard capabilities

| Item | Capability |

|---|---|

| Max layer count | 56(Rigid) 24(Rigid flex) |

| Thickness | 0.2mm (Min) 8mm (Max) |

| Copper weight | 1/2oz (17.5 μm)-12oz (420 μm) |

| Minimum track width | 25 μm |

| Minimum insulation width | 25 μm |

| Minimum laser via pad and drill size | 150 μm (pad) 40 μm (drill) |

| Minimum mech via pad and drill size | 250 μm (pad) 50 μm (drill) |

| Solder mask Gap | 25 μm (Gap) |

| Impedance control | +/- 5% |

| HDI | 7+N+7 |

Standard capabilities

| Item | Capability |

|---|---|

| Material | FR4, FR4 halogen free, FR4 HTg |

| Rogers, polyimide, Arlon, Nelco | |

| Taconic, Megtron4, Megtron6 | |

| PTFE, RCC, BT resin | |

| High speed, low loss | |

| Please contact us for special material requests | |

| Surface finish | ENEPIG, ENIG, EPIG, OSP, HAL |

| Immersion tin/silver | |

| Electrolytic gold | |

| Please contact us for special surface finishes | |

| We also offer | Blind and buried Vias |

| Filled Vias (epoxy or copper) | |

| Buried resistor | |

| Buried capacitor | |

| Buried copper coin | |

| Metal backed and metal core | |

| Please contact us to get the tailor made service you deserve | |

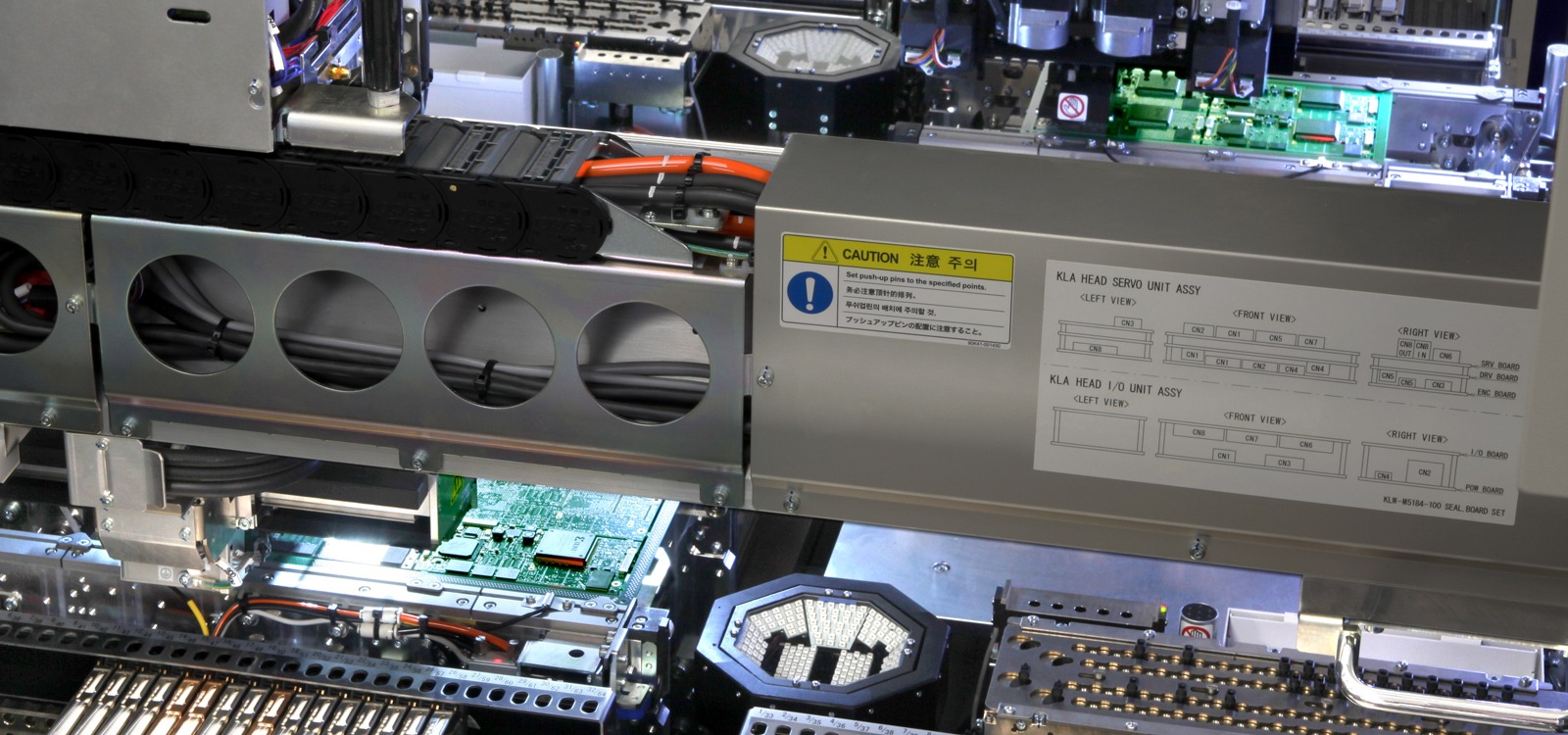

Surface mount

Interconics have recently overhauled our entire production and inspection suite to incorporate the newest class leading Yamaha equipment.

Our experienced staff are more than just operators or technicians, they are experts in their field.

At placement speeds up to 90,000 components per hour with accuracy of ±0.025mm at 3σ we offer a compromise free production service where quality and quantity are perfectly matched.

Our ESD protected production room is the perfect environment for electronic assembly, we constantly monitor and control the temperature and humidity level to ensure perfect operation conditions for our equipment, staff and most importantly your product.

Placing the smallest passive devices available 03015 (0.3mmx0.15mm) with exceptional accuracy and no compromise on speed, we are leading the way for European electronics manufacturing.

Surface mount

| Item | Capability |

|---|---|

| Print alignment accuracy | +/-0.005mm 3σ |

| Print time including inspection | 11 Seconds |

| Board size minimum | 50x50mm |

| Board size maximum | 510x460mm |

| Component size minimum | 0.3x0.15mm (03015) |

| Component size maximum | 55x100x28mm |

| Line items per machine | 140 |

| Placement accuracy | +/-0.025mm 3σ |

| Placement speed per machine line | 90,000 Components per hour |

| AOI inspection X,Y,Z resolution | 5μm |

| 3D CT X-Ray Inspection resolution | 18μm-54μm |

Get in touch today to enquire further about our services. Conveniently complete our online enquiry form or give us a call directly on +44 (0)1225 700108.